All-in-one banking for everyone

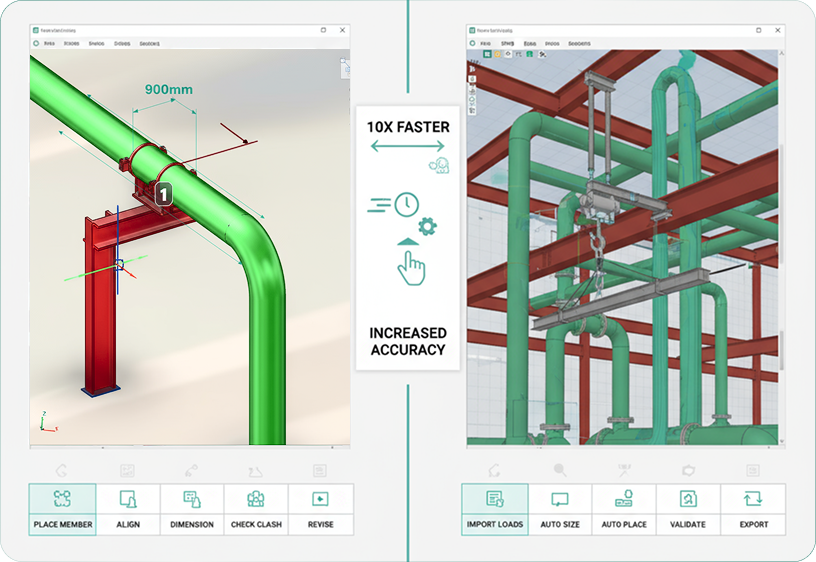

Revolutionize Your AP3D Workflow with Load Based Secondary Steel Automation

Eliminate repetitive manual modeling with a Python-driven AP3D specification that automates secondary steel design—boosting accuracy, speed, and consistency for EPC and AEC professionals.

1. Export

2. Generate

3. Import

Time-Consuming

Repeated manual entries for each load change.

Error-Prone

Human errors cause mismatched section data.

CAD-Ready Outputs

Difficult to replicate across multiple projects.

Costly Delays

Extra design cycles and rework impact budgets.

Manual Secondary Steel Design Is Slowing Down Your Projects

Traditional AP3D workflows require repetitive catalogue selections, manual property entries, and rework when loads change – leading to inefficiency and potential errors.

A Smarter, Faster Way to Model Secondary Steel

Python-based automation seamlessly integrated into AP3D to deliver a semi –

automated, load-responsive modeling experience.

-

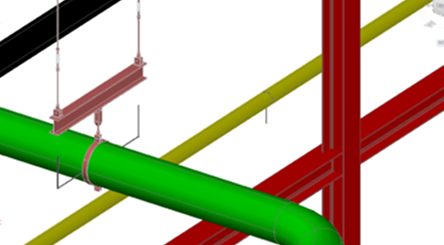

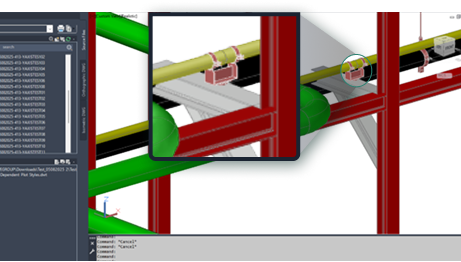

Drag-and-Drop Placement: Add steel directly into AP3D with instant dimension assignment.

-

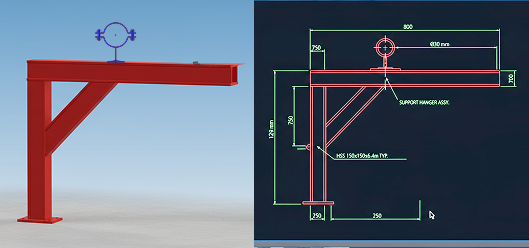

Auto Property Updates: When load changes, thickness and length update automatically.

-

Multi-Profile Support: L-Channel, I-Beam, C-Channel, Square Hollow Section.

-

Instant BOM Export: Generate Excel/CSV outputs and analysis-ready files.

Built for EPC Efficiency, Powered by iSolve Innovation

Our Load-Based Secondary Steel specification for AP3D transforms your steel modeling process through automation, integration, and intelligence.

End-to-End Integration

Seamlessly maps into AP3D’s catalogue manager.

Speed & Accuracy

Load-driven auto-adjustment eliminates manual rework.

Cost Efficiency

Generate BOMs instantly for procurement and analysis.

Scalable & Flexible

Works across diverse steel profiles and design scenarios.

Future-Ready

Extendable to integrate with other EPC tools and BIM environments.

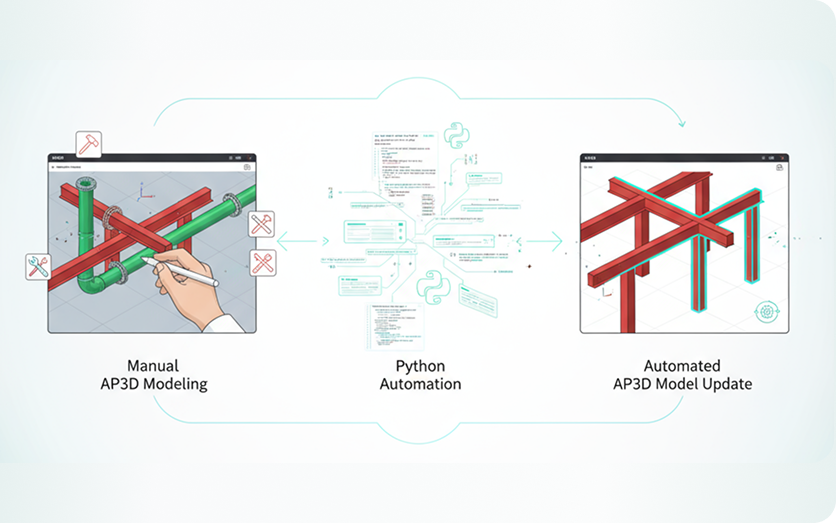

From Manual Repetition to Automated Precision

Transform how engineers, designers, and procurement teams work together.

Automated Load-Based Part Selection

Dimensions adjust instantly as load values change.

Integrated BOM & Reporting Tools

Export Excel/CSV BOMs and 3D model data.

Drag & Drop Placement

Place secondary steel directly in your AP3D environment.

Dynamic Property Updates

No re-modeling needed — the system recalculates dimensions automatically.

Consistency & Standardization

Python spec ensures uniformity across all steel sections.

Time Savings

Up to 70–80% reduction in modeling time.

A Simple, Powerful Workflow for Smart Steel Design

Python Spec Creation

Integration with AP3D

Drag & Drop Placement

Automatic Update on Load Change

Export & Reporting

Automation That Scales Across Project Types

-

Large-scale plant projects.

-

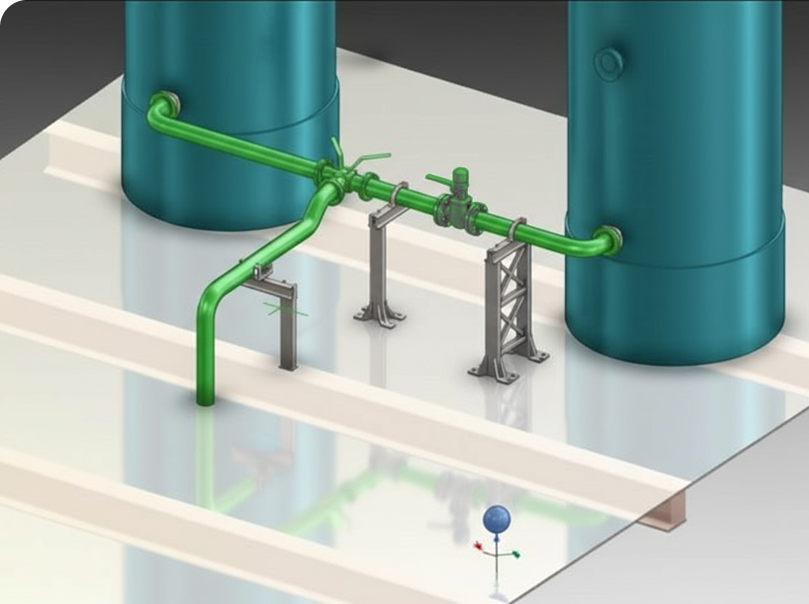

Piping support systems with variable loads.

-

Multi-discipline secondary steel integration in AP3D.

-

Projects requiring frequent load change recalculations.

Discover how automation transforms your AP3D workflows into intelligent, load-responsive design systems.